TM600-4-5 PROOFER

4 or 5 section automated proofer for 6-wide Century Midsize systems, 6 donuts per basket, compatible with C16-24 fryer.

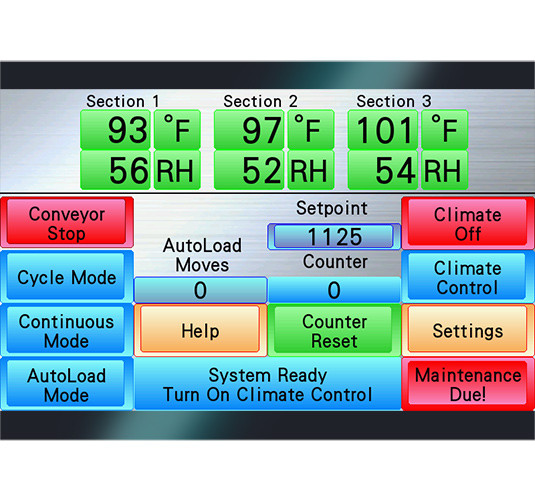

Belshaw’s TM proofer series allows donut producers to specify the best possible proofer configuration for their donut line. Proofers operate virtually free of flour dust, using teflon-coated baskets and Belshaw’s Active Release System. PLC touchscreen control, and numerous safety and other features make the proofer easy to use and help to assure uninterrupted operation. Proofers are available in 4 or 5 modular sections with each section offering additional capacity. (Note: for C18-24 system proofing, consult your Belshaw Industrial Sales manager. TM proofers contain up to 5 sections, which may not be sufficient for C18-24 systems.)

Donuts per basket

6

Typical temperature

95° to 115° F (35° to 46° C)

Typical relative humidity

50% to 65%

Typical proof time

30 to 50 minutes

Typical # of sections, C16-24 system

4 (short proof) or 5 (long proof)

Maximum loaded baskets in proofing chamber (4 sections)

1048

Maximum loaded baskets in proofing chamber (5 sections)

1311