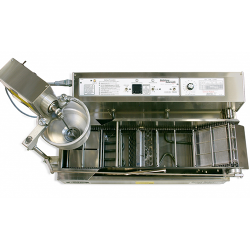

DONUT ROBOT® MARK VI

4-wide automatic fryer for cake and yeast raised donuts up to 3½” (89 mm). Capacity 88 dozen/hour, with electric power and heat.

For making a variety of both Cake and Yeast Raised donuts, Donut Robot® Mark VI is the solution. It produces at about the same rate as an Open Kettle fryer, while the consistent frying time and turning time delivers improved quality. This consistency also allows donuts to absorb less shortening than standard kettle frying.

Mark VI does not include a cake donut depositor as standard equipment. Instead, you can choose either a Type F depositor or the Dual Automatic depositor. Type F offers the full range of plungers for crullers, krinkles, sticks, balls, plain rings and Old Fashion’s. The Dual Automatic depositor makes plain ring or Old Fashion donuts only.

Donut size is limited to 3½” (89 mm). For donuts up to 4″ (102 mm), choose the Donut Robot Mark VI (Deep). The EZMelt and Feed Table accessories are essential to running a Mark VI system. Other accessories, such as proofer, glazer, and icer, are optional.

Type of donut

Cake and Yeast Raised

Donut size

Up to 3½” (89 mm)

Capacity

1060 per hour (88 dozen) @120 seconds frying time

Power

All worldwide 3-phase voltages, 12 to 15 KW

Certifications

UL, CSA, NSF, CE

Features

No standing over the fryer, no turning with sticks, no lifting screens. Donuts are deposited, fried and dispensed automatically onto a Rack Loader for sugaring, icing or glazing. A Donut Robot® makes it easier and more fun to make high quality donuts. Watch employees take charge of the whole process!

- Electronic temperature controller – holds correct temperature much better than old style thermostats.

- Holds 4 donuts per conveyor row.

- Requires EZMelt34 Melter-Filter to handle filtration and topping up shortening in fryer. (See Related Products, below)

- Requires Feed Table and Trays/Cloths to insert Yeast Raised donuts. (See Related Products, below)

- For Cake Donuts, choose either Type F Depositor or Dual Automatic Depositor. (See Related Products, below)

- After frying, dispenses donuts onto Glazing Screens in a Rack Loader. (See Related Products, below)

- Available with Support Table with holes precut for Drain, Rack Loader and bolts for holding down the fryer.

- Adjustable frying time from 60 to 300 seconds.

- Normally requires a ventilation and fire suppression hood